My 3D printed tender kits for Union Pacific’s excursion trains are now available in several scales. The kits come with 3D printed headlights, or more correctly, backup lights. In this post I will share with you how I finished a set of HO tenders with working backup lights.

Only one headlight will work on each tender. This will be the one at the rear and will only come on when the locomotive and tender or tenders are backing up. The headlight on the front of the tenders will be a dummy. I need the lights to work in both DC and DCC modes. To do this I am going to use Digitrax single function decoder TL1. This simple decoder only has four wires, two which go to the track and two which go to the lamp in the headlight.

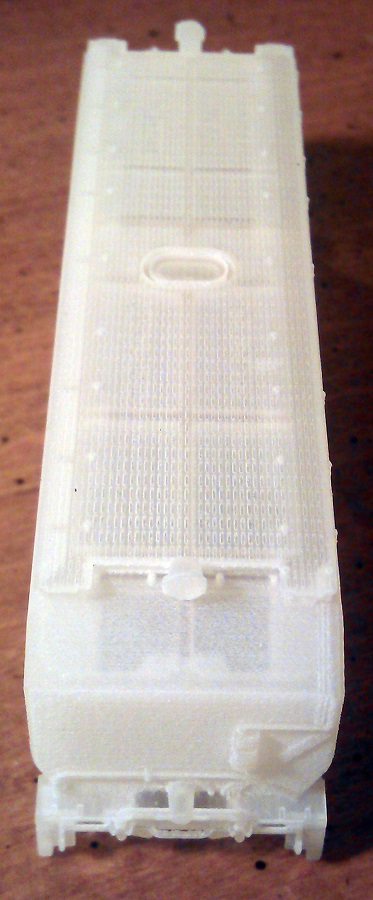

The kit, as shown below, has several parts printed in two different materials. All the high detail parts can be printed in Shapeways Frosted Detail or Frosted Ultra Detail materials. The low detail parts such as the chassis are printed in Shapeways White Strong & Flexible material. When the kit arrives from Shapeways the headlights are attached to the loop that joins the ladders together; in the image below I have cut the loop and removed the ladders.

The first thing to do is to work out how to collect power from the rails and get it into the body of the tender. To do this I am going to use metal wheels with axle wipers. One truck will collect power from the left rail, the other will collect from the right rail.

The trucks that come with the kit, as pictured below, are designed to take Proto 2000 33″ metal wheels from Walthers. The trucks are fixed to the chassis with 3D printed bolster pins that simply push in.

Although the Proto 2000 wheel sets have metal wheels the axle is made from plastic which is no use for picking up power. A good alternative are Intermountain’s 33″ wheel sets. These have metal wheels and a metal axle and one of the wheels is electrically isolated from the axle. However using these does cause a problem. The point to point dimension of the Intermountain wheel sets is slighty smaller than the Proto 2000 ones. This means that the wheel sets will fall out when the tender is picked up. To solve this I have used small off cuts of solid copper wire superglued into the V grove below the axle sockets as pictured below. When the trucks are the right way up and sat on the track the wheel set axles will be resting against the top of the axle socket; the copper wire simply stops them from falling out.

The next issue is how to transfer the power from the axle wipers up into the tender. A flexible wire is the easiest way but the position of the wire can cause complications. The further away from the bolster pin the wire is the more it will rotate as the tender runs around a bend. A crescent shape will need to be cut into the chassis to receive the wire. The maximum radius that the tender will be able to negotiate will depend on the size of the crescent. An alternative to this is to run the flexible wire up through the bolster pin. Because the HO kit is a scaled up version of the N Scale kit the bolster pins are quite big.

I used a small drill bit in a pin vice to drill a pilot hole through the bolster pin. The head of the bolster pin was printed with a hole through the thicker section to reduce material, which helps guide the drill through squarely.

Then I fitted the bolster pins into the chassis and used the larger drill bit to drill all the way through. The size of the drill bit depends on the wire and wants to be just a bit bigger to allow the wire to pass through easily.

The bolster pins were then removed and any swarf was removed from the holes.

Next come the fitting of the wheel sets. It is very important to note their orientation. In the image below the wheel set on the left is electrically connected to the wheel at the top. The wheel set on the right is electrically connected to the wheel at the bottom, you can see the plastic isolator where the top wheel joins the axle.

It is important to get all the axles in the same truck orientated the same way around. otherwise the truck will cause an electrical short. Because the trucks are the same, just rotated 180° you can insert the wheel sets the same way round in both, then when they are fitted to the tender one will pick up on one rail and one will pick up in the other.

The trucks can now be fitted to the chassis as shown below.

Doing a rolling test at this stage is a good idea to ensure the wheels run freely.

To make the axle wipers I have used 1mm wide phosphor bronze strips about 45mm (1.771″) long.

The wiper strip is pushed through the axles. It goes under the two outer axles and on top of the middle one. That way it will utilize all three axles to collect power.

Then using my fingers I bent the ends of the wiper strip around the outer axles. This will stop the strip from rolling out and moving as I work on it..

Using my soldering iron I tinned up the strip just above the hole in the bolster pin.

Then one of the wires from the DCC decoder was fed through the chassis and bolster pin. A small section at the end of the wire was striped back and tinned with solder. The end was then bent over by 90°. In the image below this has been done to the black wire.

This hook can then be positioned over the tinned wiper strip and with a quick touch of the soldering iron they can be joined.

There is a risk with this configuration that the axle wiper will rotate and run diagonally across the axles. If the wiper strip touched a wheel that is isolated from the axle it will cause a short. There are two things that can be done to prevent this.

The first is to remove one of the end wheel sets, this will cause the wiper strip to fall out. If you gently roll the ends of the wiper strip around a bit further between your fingers and then refit the wheel set not only will it be a tighter fit almost preventing the wiper strip from going diagonally, it should also improve the contact with the axles thereby improving the power pickup. This can add drag to the wheel sets and you should check that the tender still rolls well once this has been done.

The second is to add a guide which the wiper strip will run between. To do this I used some of the same solid copper wire I used in the V slots of the trucks. I bent the wire into the shape shown below.

This bent wire shape fits down through the second hole in the truck frame as shown below. Once I was happy with the fit they were superglued in place .

The forked ends protrude down on either side of the wiper strip giving some room to move but preventing it from going diagonal. The other end is held in place by the wire coming through the bolster pin.

Below is a close up of a finished truck with a fixed axle wiper collecting power from all three axles.

This now completes the tender chassis, in next week’s post I will show you how the working tender headlights were fitted and how the tenders were finished.

With the large surface area of the O scale tenders this made the job much faster and helped me get into all the tricky areas such as around the grab-rail posts. These can be delicate and the toothbrush has an increased possibility of knocking them off.

With the large surface area of the O scale tenders this made the job much faster and helped me get into all the tricky areas such as around the grab-rail posts. These can be delicate and the toothbrush has an increased possibility of knocking them off.

As with the DD35 Additions kit the DT6-6-2000’s handrails can cut out of the brass plate with a sharp craft knife and simply glued into place. Below are some work-in-progress shots taken by Brian Stewart of one of his DT6-6-2000s, the brass stands out well against his black paint work.

As with the DD35 Additions kit the DT6-6-2000’s handrails can cut out of the brass plate with a sharp craft knife and simply glued into place. Below are some work-in-progress shots taken by Brian Stewart of one of his DT6-6-2000s, the brass stands out well against his black paint work.

You must be logged in to post a comment.