The N Scale Bachmann F7 has had three revisions to date and the most recent one, made available in 2013, is supplied with DCC. But what about the first two? In this post I will show you how I add DCC to the locomotives in a cost-effective way.

The Bachamm F7 over all is not a bad locomotive; it has great polling power and the body work, although not as good as the Intermountain model, is nice. They do tend to run a bit noisily so installing a sound decoder for me was not an option. As I have several of these, installing a basic decoder in each starts to add up, so again I am going to use one decoder to power two locomotives. When doing this it is important that the locomotives run at similar speeds when used together on DC power. Luckily these do, but if yours don’t I have already covered a topic like this and you can read about it here.

The F7 A & B set I am converting to DCC, as shown above, is the second version but both first ‘Plus’ version and the second ‘Spectrum’ version are very similar in chassis shape and design so this method will work for both. You can read about the difference in Spookshows N Scale encyclopedia here.

With the shells removed, as you can see below, both the A and B units are exactly the same with the exception of the A unit having a light bulb pushed into the hole at the front. To remove the shells simply spread them at the fuel tank and they will un clip then lift off. You will also see that the chassis totally fills the A unit shell leaving no room for a DCC decoder to be installed. But because the B unit has the same chassis there is space in the B unit where the cab would have been so I will be putting my decoder there.

There are no wires inside the chassis, which is split into two, and the light bulb simply picks up power by touching the chassis halves. A down side to this when running on DC is the light comes on in reverse as well. And for DCC, the motor picks up its power in the same way so we will need to isolate it.

To take the chassis apart is fairly simple. First remove the fuel tank by undoing the screw in the middle.

Then undo the two chassis screws in the left half and it will lift off.

Turning the left half over you will see a spring projecting out of the chassis. This is the bottom motor contact that connects the left half to the motor. This spring needs to be removed simply by pulling it out.

With the two halves separated the whole assembly will come apart. The motor simply lifts out and the truck assemblies will already be free.

The right half of the chassis has a stub that sticks out and connects to the top motor contact.

This stub needs to be removed. This can done with a good pair of large side snips and a file. The chassis is made from a fairly soft metal so it files down quickly. In the photo above you will also see the inside of the black tape that has been put across the holes in the chassis. I believe Bachamnn added this to the second version to prevent particles getting into the motor winding. Also as it is sticky on the inside it will catch any particles thrown off the motor brushes. You can see some of those just below the stub. Filling the stub will create metal fillings which you also don’t want to get in your motor so once the stub has gone remove the black tape and clean the chassis half to remove all the filings. A stiff brush will normaly do this.

With the chassis half clean, you can do a test fit with the motor to make sure the motor contacts to not touch the chassis.

To do a proper test the chassis can be resembled with just the motor in it and you can do a continuity test with a volt meter. Dont forget to put the little plastic spacers back in, there is one for each screw and one in the fuel tank.

Next we need to create a path for the bottom motor wire. As there is no room inside, the wire will have to come up the outside of the chassis but as the shell is a snug fit around the motor, there is still no room.

So in order to make room I have filled a V grove up the side of the right chassis half.

The grove also continues round under the fuel tank. The grove needs to be just big enough to take the wire you are using so the face of the chassis and wire will be flush.

Once any metal fillings have been removed the chassis is now ready and we can turn our attention to the motor. The motor body is already isolated from the contacts so all we need to do is add our wires to the contacts. Although we can change this later it is useful to add the right wires onto the motor now so we know which is the positive side. Normally orange is the positive motor wire and gray is the negative. But there is no indication on the motor as to which is which. On my work bench I have a DC controller with a test track and a pair of wires. When a train is running forwards and to the left the right rail is my positive, colored red, and the left is my negative, colored back. Touching the red and black wires onto the contacts will make the motor spin and in the configuration shown below you want the motor to spin anticlockwise. That would be the same as forwards to the left.

To add the wires I quickly heat the contacts with the soldering iron, for one to two seconds, then add a little bit of solder just to tin the contact. You don’t want to over heat the contact is it is a perfect conductor of heat and there are plastic parts inside. Next I tin the end of my wire, hold it to the contact and quickly touch it with the iron. The two tinned areas fuse and you have a good connection. Note the wires need to be long enough to run up inside the locomotive and across to the B unit.

Before re-assembling the chassis I also change the couplings on the loco. When these where being run under DC I used Unimate couplings from Red Caboose. These provide a nice close couple that will not come undone on the track however as I will now have wires running between my locos I don’t want them to come uncoupled at all. To do this I will replace the Unimates between the A and B unit with one of my fixed link couplings.

In the image below you can see the underside of the Bachamnn power truck. Just to the right of the tuck and before the coupling box are a pair of pins that can be squeezed together with a pair of needle nose tweezers. This will cause the coupler box to pop off.

Inside the coupler box is a spring that fixes over the peg on the back of the coupler.

My 3D printed fixed coupler is a direct replacement for the old Rapido style couplers so drops right into the Bachmann coupler box.

For now I only fixed one truck to the fixed link but you could do two, one from the A unit and one from the B unit, at this point.

Now the chassis can be reassembled. Note the wire form the bottom motor contact is coming out the bottom of the chassis in front of the plastic spacer. (I know the wire is brown and not gray but I have run out of gray!). Also when you refit the tracks make sure the metal contact for power pickup is rubbing against the underside of the chassis not the inside as this will prevent the trucks from rotating.

The brown wire (bottom motor connection) can now be placed in V grove that was filed earlier and the fuel tank can be replaced. Also I have put some Kapton Tape over the holes in the chassis to replace the black tape I removed, this also holds the wire in place.

Now the motor is isolated and wired up the next two wires are the power supply. On top of the chassis are four nubs that the shell sits onto. Interstingly these are slightly narrower on the bottom than they are on the top so all I do is wrap the end if my wire around the base of the nub a full 180° and solder it in place. I have yet to have one of these fail. And as long as there is nothing sticking up above the top of the nub the shell will still fit. The red wire goes to the right side and the black, or purple in my case, goes to the left. I must order some more different colored wire!

The last wires, for the A unit, are for the light. The standard light is a light bulb and these can be power-hungry and get hot. So I replace mine with warm white LEDs. Below is a comparison with standard 3mm LED on the right and a 1.8mm LED on the left which I will be using.

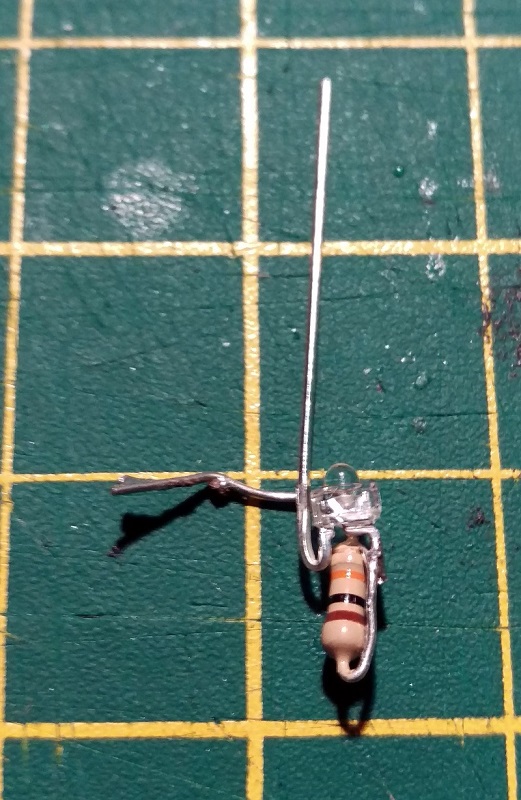

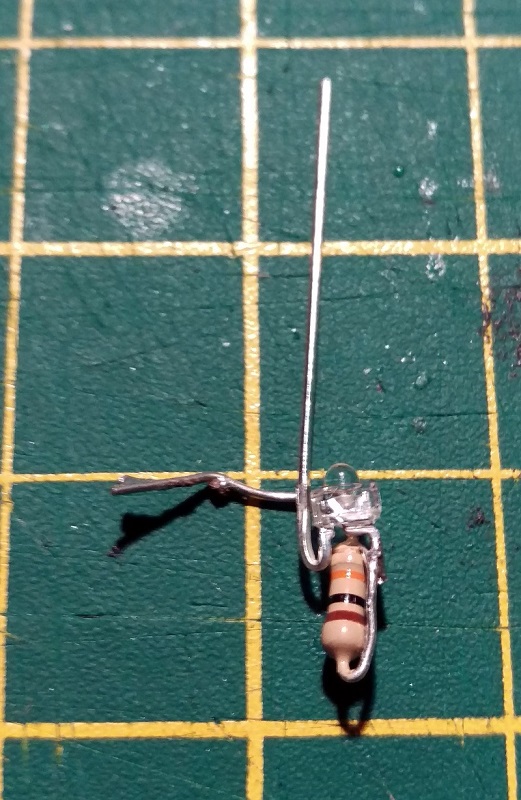

As all LEDs need a resistor in line I make the resistor a part of the headlight by folding one of the resistor legs back onto its self and soldering it to the LED.

Then I wrap it all in Kapton Tape to prevent it shorting.

Finally I trim back the legs ready to solder on the wires.

The LED will sit in the same place as the light bulb. To protect against shorts I put a strip of Kapton Tape over the nose then cut out the hole with a sharp knife.

The LED light assembly then pushes into the hole and the legs, sitting on top of the Kapton Tape, can be soldered too. As LEDs only work in one direction it is important to know which is the positive and negative. The blue wire, matching the decoder, is the positive.

With all the wires in place they can now be taped down with Kapton Tape so they are tidy and clear of the shell. Check to make sure the trucks rotate freely.

To fit the shell I you could simply run the wires through the window in the connecting door at the back but this can be really tricky so using a sharp knife I simply remove the plastic under the window.

This allows the shell to be lowered onto the chassis without pulling or pushing on the wires.

When it comes to the B unit I do exactly the same, except the wires run to the front and there is no light.

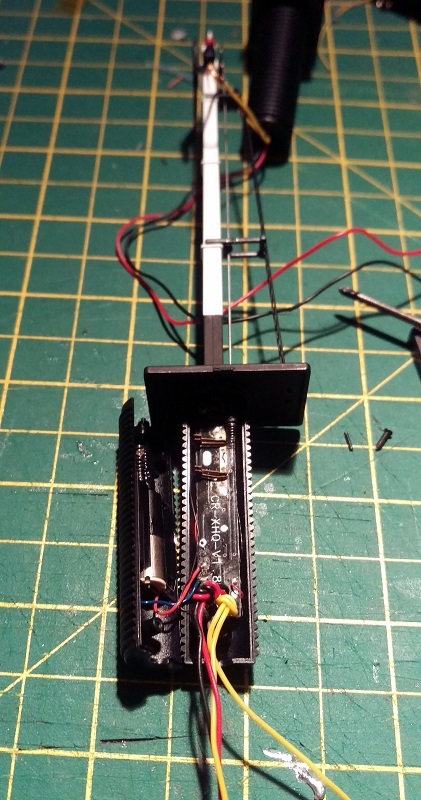

To join all the wires up I like to uses little bits of cooper strip board.

These are then superglued to the nose of the B unit. You could use one piece and glue it to both sides of the chassis but this would mean the unit could not be taken apart for repair if needed. You also need to make sure the DCC decoder will fit behind the cooper strip boards and they do not protrude out side of the chassis so the shell will still fit.

Once you are happy with the placement of the cooper strip board, solder the wires together, orange to orange etc. The red and purple (black) can go directly onto the B unit chassis. At this stage there are a few checks that you should make. First, using a volt meter set to a continuity check, check that the left B unit chassis is connected to the left A Unit chassis, and repeat for the right. Secondly check that the left and right chassis are not connected to each other. Thirdly check that none of the chassis are connected to any of the cooper strip board terminals. Then using 12v DC wires from a controller test that both motors are running the same direction when you connect them to the orange and brown (gray) wires and finally test the headlight works when you connect the 12v DC wires to the blue and white wires.

I also connected the fixed link coupler to the front truck of the B unit at this stage.

The last stage is to solder the six decoder wires to the copper strip board terminals and chassis points. I have used a Digitrax DN163, it was a bit of a tight fit because this decoder has a plug on it making it thicker than normal but most N or Z scale decoders will fit.

I cut the front door of the B unit shell to fit over the wires the same as I did with the A unit and fitted it onto the chassis. And there you go; two powered locomotives connected with a draw bar, which is prototypical, and one decoder.

But there is one more thing that you can do to make this even better and that is to have four locomotives with two decoders.

Normally the locomotives would all have different numbers but to make things easy I have configured the two DCC decoders to be both the same address and switched the rear pair to run in reverse as their forward direction. This means you don’t have to consist the locomotives, and they won’t take up two slots in your DCC command station. This can all be done by changing the configuration variables or CV values; which can be fairly in-depth subject so it is something I will cover in a later post.

Normally the locomotives would all have different numbers but to make things easy I have configured the two DCC decoders to be both the same address and switched the rear pair to run in reverse as their forward direction. This means you don’t have to consist the locomotives, and they won’t take up two slots in your DCC command station. This can all be done by changing the configuration variables or CV values; which can be fairly in-depth subject so it is something I will cover in a later post.

The problem now is the point blades are again reliant on the contact with the stock rail, however Peco have made this easy to fix. As you can see in the image below, next to the slots where we removed the connecting wire, they have omitted some of the plastic allowing access to the underside of the stock rails and the top of the point blades. On older points this access is not there but can easily be made with a sharp knife.

The problem now is the point blades are again reliant on the contact with the stock rail, however Peco have made this easy to fix. As you can see in the image below, next to the slots where we removed the connecting wire, they have omitted some of the plastic allowing access to the underside of the stock rails and the top of the point blades. On older points this access is not there but can easily be made with a sharp knife.

Normally the locomotives would all have different numbers but to make things easy I have configured the two DCC decoders to be both the same address and switched the rear pair to run in reverse as their forward direction. This means you don’t have to consist the locomotives, and they won’t take up two slots in your DCC command station. This can all be done by changing the configuration variables or CV values; which can be fairly in-depth subject so it is something I will cover in a later post.

Normally the locomotives would all have different numbers but to make things easy I have configured the two DCC decoders to be both the same address and switched the rear pair to run in reverse as their forward direction. This means you don’t have to consist the locomotives, and they won’t take up two slots in your DCC command station. This can all be done by changing the configuration variables or CV values; which can be fairly in-depth subject so it is something I will cover in a later post.

You must be logged in to post a comment.