At the beginning of July I showed you how I install ESU LokSound decoders in my C-855 kits. You can find the post here. This week I’ll show you how I added a small stay alive system to improve the performance of the locomotives.

With just the ESU LokSound decoder and speaker installed in the C-855 chassis, as shown below, the loco ran reasonably well but it did hesitate a few times on some point work.

This hesitation was down to dirty contacts in the pickups. As the power supply was briefly removed from the decoder the locomotive came to a stop and the sounds went off, then it went through its start up cycle again. As the other two locos in the set are still trying to run, this can be fairly annoying. As well as cleaning the contacts and wheels I decided to add some stay alive capacitance to each locomotive. A stay alive system is just what it sounds like; it keeps the decoder alive when the power is briefly lost. ESU do sell their own stay alive devices, which are very good, but they’re fairly expensive, so I prefer to make my own which also allows me to make them to fit whatever space I have. The only components I use are capacitors, a resistor and a diode.

The capacitors are 220uF 16Vdc Tantalum capacitors, the resistor is a 100Ω 0.25w and the diode is a 1N4007. These are all parts which are readily available from most electrical stores or online.

The capacitor is designed to be fitted to a circuit board and is very small, which is ideal for N Scale locomotives. 220uF means the unit has a capacitance of 220 micro farads. You can get similar size capacitors with more capacitance such as 330uF but the price goes up. The 16Vdc refers to the maximum amount of voltage the capacitor can handle; because N scale DCC systems run between 12v and 16v, and the decoder drops the voltage by around a 1.5v, the capacitor will be receiving between 10.5 and 14v, so I find these are fine.

Be careful when buying these Tantalum capacitors; there are a lot of cheap ones out there with a low quality control. It may say 16Vdc but if they’re cheap that may be an approximation. If you put too many volts onto a Tantalum capacitor it will blow up, very loudly and dramatically. The best way I can describe it is like a Roman candle. And you don’t want that happening inside your locomotive! The SOO SD50 below just had that happen with some cheap capacitors and the flames went up in the air by about a foot and blew a hole in the shell before I had a chance to cut the power. So I would recommend a quality supplier.

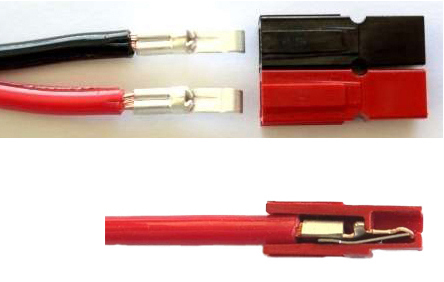

The Tantalum capacitors have two metal tabs on the rear to solder to and a strip on one side to indicate the positive connection.

For these locomotives I’ll be using a bank of three Tantalum capacitors connected in parallel, which will give 660uF. That isn’t a lot and won’t keep the motor turning, but it will give a few seconds to the decoder to keep the sound running, which is all I need. With all three locomotives working together the momentum and power of two out of three will jog a stalled loco enough to get it moving again without the decoder losing power and restarting itself. I’ve glued these three together with superglue.

I’m going to put the capacitors in front of the speaker. There is room to put in more, and normally the more you have, the better, but I want the space for the other parts.

The resistor and diode perform two important tasks. They are both connected to the positive capacitor terminal and positive (blue wire) connection on the decoder. The resistor is used when the system is charging. Power flows from the positive connector on the decoder into the capacitor to charge it. As it passes through the resistor the current is reduced, which causes the capacitor to charge slower than normal. Otherwise the DCC command station would detect the inrush of current and think there’s a short circuit when you first put the loco on the track. The diode is there to bypass the resistor when the stay alive system is in use. If the track power is lost the power flows from the capacitor back into the positive connector, but we don’t want any resistance. As the diode wire is thicker than the resistor’s I wrap the smaller wire around the larger, as shown below.

I then solder the connections.

And lastly trim off the excess.

The new ESU Loksound V5 Micro decoders have a Next 18 plug, as described in the earlier post, as well as six solder pads.

The two we’re interested in are shown below. I have tinned the solder pads with solder. The one on the right is the positive connection, which is the same as the blue wire. The left pad is the DC negative or common ground for the decoder.

To join all the parts together I start with the capacitors. Using the off-cuts from the resistor I join the capacitors together by soldering the wire to each pad.

I then solder the diode and resistor to the positive side ensuring the band on the diode is on the far side from the capacitors. This is because DC power only flows one way through a diode, towards the band, and we want it to flow out of the capacitors to bypass the resistor when in use.

I then solder a wire to the diode and resistor and another to the negative side.

The assembly is then wrapped in Kapton tape, ensuring there is no connection between the negative and positive terminals, and fix it into the loco.

At the other end I solder the wires to the corresponding solder pads on the decoder, ensuring there is enough wire to allow the decoder to be plugged back into the socket.

The decoder can then be plugged back in and the chassis is ready to go.

All three chassis have now been fitted with stay alive units and the bodies have been fitted, but you’ll need to wait until next week to hear what they sound like when I’ll also show you how to program the decoders so that each of the six Alco 251C prime movers sound slightly different.

However as the sand boxes have been painted it’s possible the square holes are blocked with paint. If that’s the case they can be opened up with a 0.4mm drill in a pin vice as shown below. No 3D printed material needs to be removed and a few twists should cut through any paint blocking the hole.

However as the sand boxes have been painted it’s possible the square holes are blocked with paint. If that’s the case they can be opened up with a 0.4mm drill in a pin vice as shown below. No 3D printed material needs to be removed and a few twists should cut through any paint blocking the hole.

The crank in the image above is rotated clockwise and the crank in the image below is rotated anticlockwise by the same amount.

The crank in the image above is rotated clockwise and the crank in the image below is rotated anticlockwise by the same amount.

You must be logged in to post a comment.