In February of this year I shared with you my set of replacement 3D printed gears for the Bachmann N Scale 4-8-4, 3rd Generation. You can find the post here.

At the end of the post I needed to make some modifications to the gears as the axels were still a little too loose on the wheels and the twin transfer gear was way too loose. These changes were made and another set was 3D printed.

This time all the gears fitted well into the chassis, but I think I still have a problem with the twin gear as the motor struggles to drive all the gears. Either the larger set are oversize, causing resistance between the gear and the worm, or the smaller set don’t have a deep enough trough between the teeth, which means the axel gears push the twin gear up into the worm.

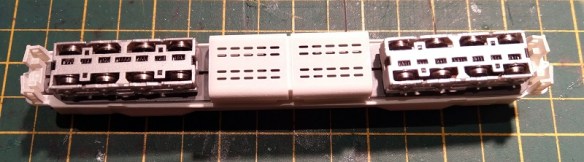

With the original twin gear fitted, and all the other 3D printed gears fitted, the assembly runs smoothly. Below you can see the axels fitted onto the wheels with the chassis plate installed.

With the entire chassis assembled I started testing the gearing and discovered that there was a bind at the same point in every rotation. After a little adjustment I was able to get it to run much smother. However, on reflection the next time I do this when fitting the gears to the first set of wheels, as shown above, I’ll attempt to get the gears positioned at the exact same point on each wheel, as I think it was this that caused the issue. If, as with diesel locomotives, there are no side rods, the position of the gears is not so critical as they will find their place. Or if there are no internal gears, simply side rods as with the HO 4-8-4, then it’s just the quartering which needs to be correct. But as this loco has both internal gears and side rods, the quartering needs to be correct as does the gear positions relative to each other.

Below is a quick video of the chassis running with power supplied direct to the motor.

I’ll make the adjustments to the twin gears and do another test print, but in the meantime if you’re keen to get your N scale 4-8-4 back on the road and are happy to use all the other gears then a set is available here. In most cases, these 3rd generation 4-8-4 locos only need the axel gears to make a full repair as it’s the axels that split.

Once the new set arrives I’ll update you with the progress in a later post.

This needs to be cut off and that can be done with pair of side snips.

This needs to be cut off and that can be done with pair of side snips.

Next week I’ll have some real steam to share with you as I spent a day at ‘The Great Dorset Steam Fair 2018’.

Next week I’ll have some real steam to share with you as I spent a day at ‘The Great Dorset Steam Fair 2018’.

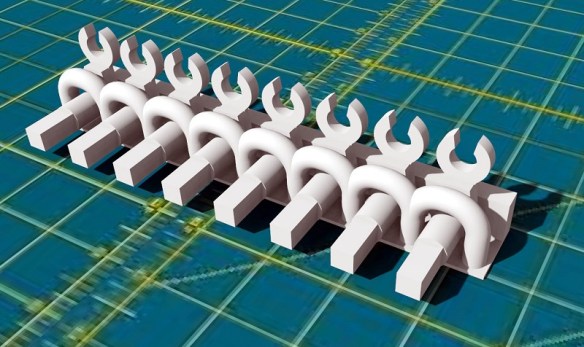

This did help and made it much easier to reinstall the rivet. But the issue of re-flaring the rivet was still a problem and I was finding it hard to do as I couldn’t get a supply of new rivets. This lead me to start cutting part of the loop away to leave a ‘C’ shape which could be forced over the rivet. As it is a ‘C’ shape it would not fall back off the rivet and the rivet didn’t need to be un-flared in the first place. The original peg, what was left of it, could be cut away and the new one could simply be clipped in.

This did help and made it much easier to reinstall the rivet. But the issue of re-flaring the rivet was still a problem and I was finding it hard to do as I couldn’t get a supply of new rivets. This lead me to start cutting part of the loop away to leave a ‘C’ shape which could be forced over the rivet. As it is a ‘C’ shape it would not fall back off the rivet and the rivet didn’t need to be un-flared in the first place. The original peg, what was left of it, could be cut away and the new one could simply be clipped in. Then in June 2017 when Shapeways restructured their pricing system this model became rather expensive as each individual part had an additional $1 handling charge added to the cost. But the answer is my new Mk4 version of the crank pin which you can see below.

Then in June 2017 when Shapeways restructured their pricing system this model became rather expensive as each individual part had an additional $1 handling charge added to the cost. But the answer is my new Mk4 version of the crank pin which you can see below.

You must be logged in to post a comment.