In last weeks post I promised to share with you some of my newly-weathered stock so that is exactly what I’m going to do.

I have a range of rolling stock from different manufacturers and a lot of the freight cars, although they are very nice, some do seem a bit brightly coloured. To be fair a lot of them would have been this way when they rolled out of the factory for the fist time. But after spending some time of the rails everything gets dirty, and even rusty as they get older.

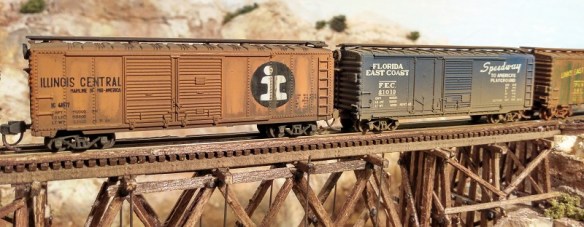

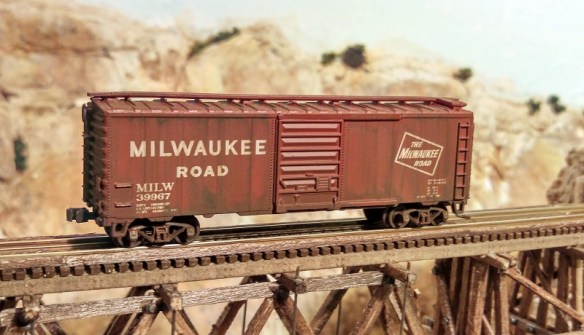

I think they should look more like this.

Here are some closeups shots.

The next three where identical before weathering.

As a comparison; below is a factory weathered freight car, on the left, alongside my weathered freight cars.

As a comparison; below is a factory weathered freight car, on the left, alongside my weathered freight cars.

One of the things I didn’t like about the factory weathered freight car was the trucks, they look too shiny and new compared to the rest.

Below is a short video showing a train passing with regular stock followed by a train with the new weathered stock.

So how did I do this? Well given that time is precious, as those waiting for projects to be draw will appreciate, I’ve found the best solution. Get somebody else to do it!

These were all airbrushed by Model Railway Solutions. MRS provide all sorts of modeling solutions from flat pack baseboard construction, all the way up to complete model railways built to exhibition standards.

The weathering service is very reasonable and they are happy to work with large batch projects which can reduce the shipping costs when sending models from overseas.

Here are some of the other models that were on the work bench when I collected this batch.

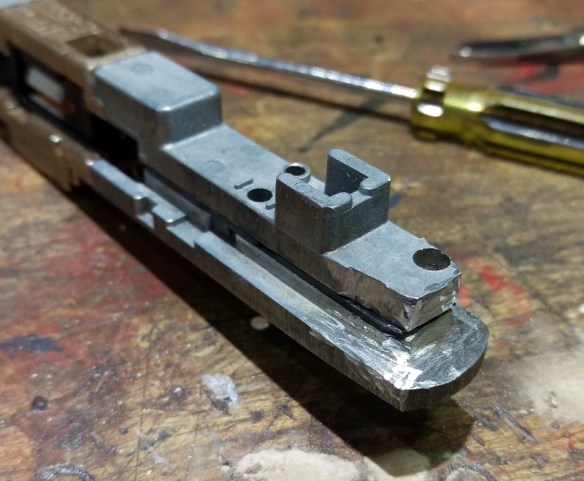

This is an N gauge southern region Merchant Navy class locomotive.

This is a OO Gauge 9F made by Hornby.

Although the main body is dull and dirty the running gear looks wet and oily, these photos don’t do the locomotive justice.

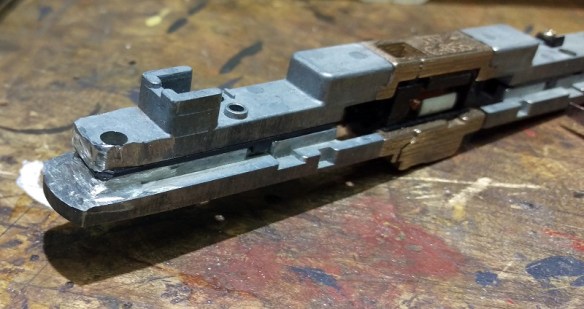

Here is a BR Standard Class 4MT made by bachmann.

I liked the rusted areas around the tender water filling area.

The real coal in the tender was also added by MRS.

Coaches also get dirty and below is a OO Gauge collett coach made by Hornby which has also had the air brush treatment.

And to pull a train of these coaches, what could be better than a GWR Castle class. Again this OO gauge model was made by Hornby and is now in a typical representation of what it would have looked like when these engines where nearing the end of their life.

Of course freight engines where not looked after anywhere near as well as the passenger locos. Below is an image of a brand new OO Gauge Hornby 2-8-0.

MRS spent some time on it and now it look like this.

It still runs as smooth as silk but in this condition you can just imagine it has seen many years of use.

MRS are happy to be contacted by phone or email and both can be found on there website. Alternatively you can always drop me a message through my contact page and will be happy to talk to them for you.

You must be logged in to post a comment.