As promised in last week’s post I have a replacement part to share with you for one of Rio Grande Southern’s famous pieces of rolling stock.

The ‘Galloping Goose’ is one of those items that Con-Cor made, and made very well, which you just fall in love with. Even though the prototype was a narrow gauge rail car and this model runs on standard N Scale track it’s a great piece of modeling, particularly because it’s so small.

This ‘Goose’ is very highly detailed and on the front is the classic cow catcher or pilot and it’s this part that I was asked to make by a fellow modeller who’s missing one.

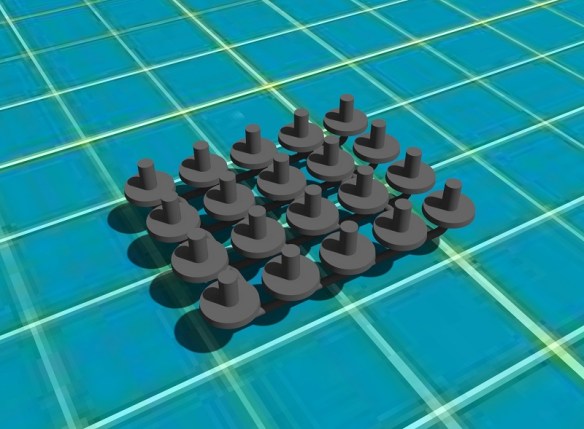

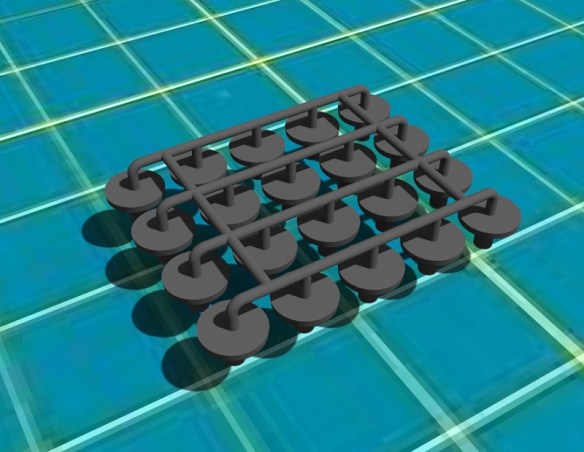

As supplied by Con-Cor the pilot comes in two forms; as shown above and with a snow plow, shown below.

The plow is a separate part which simply clips onto the pilot.

For this replacement part only the pilot section was required, so I removed the plow and measured up the pilot. The verticals are very thin on the original injection-molded part so the replacement can’t be exactly the same: having such thin 3D printed parts would be very weak. This can be overcome by increasing the depth of the verticals and making the sections larger, however all the main visible areas and mounting points will look correct. As usual I produced a rendered image of the 3D model and below you can see the pilot from several angles.

The two pegs protruding horizontally from the cross beam are all that hold the pilot to the front of the ‘Goose’. The two bars that slope upwards are purely cosmetic although on the real thing they are a part of the pilot mounting.

I will be ordering a test pice of this pilot in the next week or so. However you can order one already from the Shapeways site.

It is available as a single pilot here.

Or as a pack of two here.

The pilot has been designed to be printed in Shapeways Frosted Ultra Detail (FUD) and Frosted Extreme Detail (FXD) materials so the best detail can be obtained; after all, this part is only 10mm wide and 6mm high.

I can also make the snow plow available if anybody wants one although I expect it will not be a separate part but an entire replacement pilot with the plow permanently attached.

Next week I’ll have another small replacement part to share with you which will help step things up a gear.

You must be logged in to post a comment.