Nuts Bolts & Washers (NBWs) can be an important detail on timber bridges or trestles and can make the difference in how good they look. But in N Scale it can be a hard detail to achieve. There are commercially available products but if you need lots the price can start to climb. In this post I will share with you how I make my NBW using a cheap and effective method.

Timber bridges and trestles are usually held together with long bolts which pass though the center of timbers at intersections. The bolts are usually 3/4″ to 1″ in diameter and under the bolt head or nut is a 3″ or 4″ square cast iron washer. The washer prevents the bolt head or nut from pulling into the timber. Smaller joints are made with boat spikes which are similar large nails.

Below is a typical trestle bent I have scratch built for my new trestle module; the horizontal timbers will be fixed to the verticals using bolts. The diagonals would have been fixed using boat spikes, however given the large number of bents I have to make I have decided to omit this detail.

To make the washer plates I use black thick paper or card. Using a sharp hobby knife I cut a strip off the side of the sheet the same width as one of the washer plates. As this is for an N Scale trestle I have exaggerated the size of the washer plate to make them practical to work with; mine are about 8″ to 9″ square.

The strip is then cut into squares. As my trestle project is fairly large I will be needing lots of these so to speed things up I cut several strips at the same time. However when you cut a thin strip of paper like this it has a tendency to curl up so the trick to this is to leave the first and last part intact as in the image below.

Then the paper can be rotated and all the strips can be cut through all together. I hold the uncut strips down with my left hand as I cut with my right.

To make the bolt and nut detail I use brown thick paper or card and a hole punch.

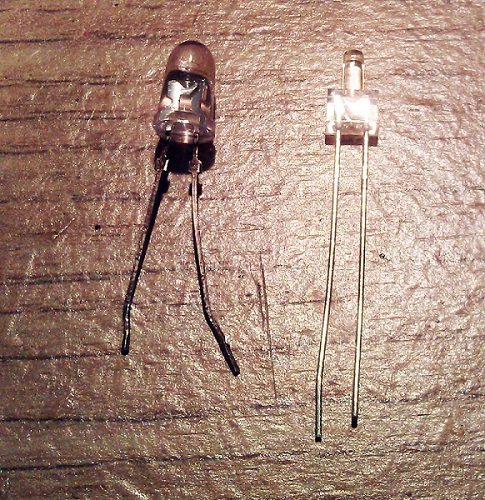

The hole punch is a simple tool that came from a hobby cardmaking kit. It is hollow so as the holes are cut the dots push up inside the tool.

To add some thickness and variation to my bolt and nut detail I like to cut the paper into rough strips and place one behind the other before making the dots. Sometimes I use two strips, sometimes three.

When I use the punch I always use a separate cutting mat as it can be fairly destructive to them. Below you can see where I have punched out a group of dots from two plies of paper. The paper looks fairly disheveled, this is because as the punch cuts through the paper it spread it apart, keeping a perfect dot inside.

The dots accumulate inside the tool. Because of the asserted pressure to cut the dots the two sheets lightly fuse together making a nice thick dot.

I keep my dots in a separate container from the washers; this makes it easer for me to quickly assemble my trestle parts.

To fit the NBW detail I use Tacky Glue This is a white glue which is already fairly sticky and sets quickly.

The particular brand of tacky glue has a nice dispenser on the bottle which allows me to put small dots where I want them. Because it starts to set fairly quickly I only do about 10 at a time. Coincidently this trestle leg only has 10 bolts.

Using tweezers I position 10 washers on the glue dots.

Then I add another glue dot on top.

Finally I add the brown paper dots on top of the washers. A few of the dots will split apart giving a nice selection of thick and thin. When the dots are positioned and pushed down some of the glue will rise up the side and glue the two parts together.

Once the glue has dried the NBW detail may look a little shiny; this is good because they would have been greased up to prevent them from rusting.

Once the glue has dried the NBW detail may look a little shiny; this is good because they would have been greased up to prevent them from rusting.

If you also wanted to add the boat spike detail this can easily and cheaply be done by placing a small dot of black paint at the desired location with a tooth pick. If the tooth pick is also pushed into the timber the indent will look like a spike head.

I have used this NBWs process with great effect for my whole N Scale trestle construction and I will share it with you once it is complete.

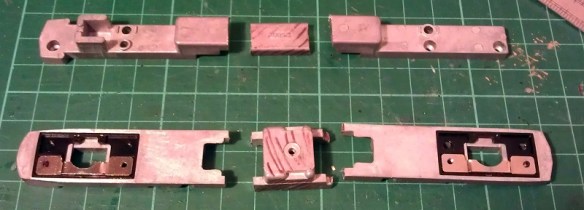

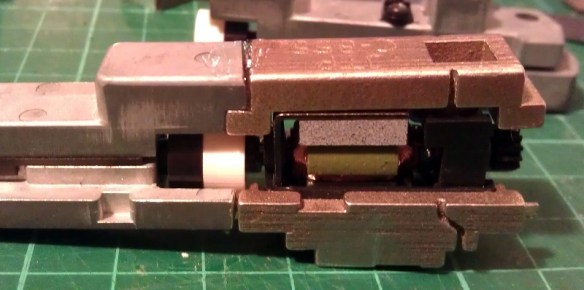

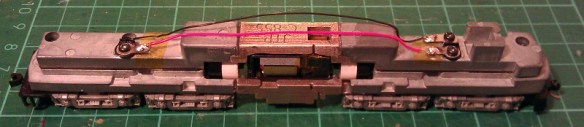

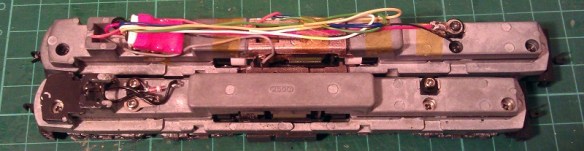

Now the top section was complete I could position and glue in the motor section. You may have noticed I left the top and bottom sections of the chassis bolted together throughout most of this. I did this to help ensure everything was in the correct place, particularly when it came to fitting the motor section. As it happened I did cut the lower front chassis section a bit short and if I had glued the whole bottom section together tightly it would have been too short. However as the chassis parts were bolted it all worked out well and below is the chassis glued together.

Now the top section was complete I could position and glue in the motor section. You may have noticed I left the top and bottom sections of the chassis bolted together throughout most of this. I did this to help ensure everything was in the correct place, particularly when it came to fitting the motor section. As it happened I did cut the lower front chassis section a bit short and if I had glued the whole bottom section together tightly it would have been too short. However as the chassis parts were bolted it all worked out well and below is the chassis glued together.

The primary chemical is chloroxylenol (C8H9ClO); the rest is pine oil, isopropanol, castor oil, soap and water.

The primary chemical is chloroxylenol (C8H9ClO); the rest is pine oil, isopropanol, castor oil, soap and water.

You must be logged in to post a comment.