In this weeks post I will share with you the first N Scale 3D printed Alco C-855 and all the accompanied parts. If you want to read more about the history of this project click here and it will open a new page listing all my posts about it.

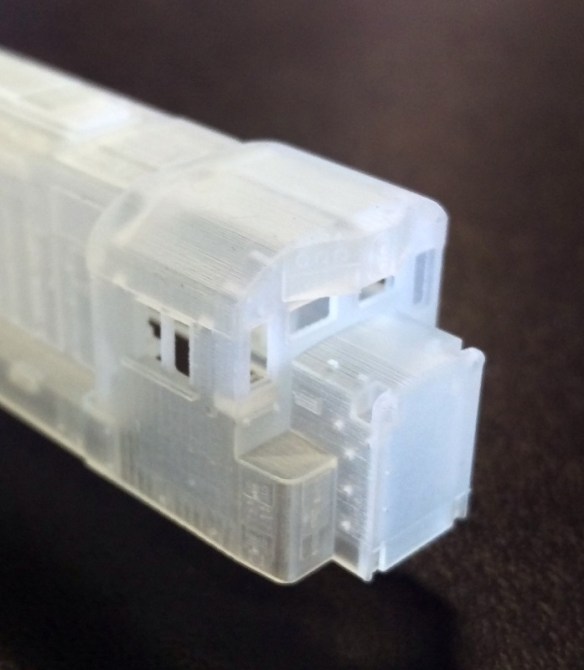

This model has been in the pipeline for a few years, so as you can imagine, I was very excited when last week the first test print arrived from Shapeways, and I must say I am very pleased with it. Below you can see all the parts as Shapeways delivered them.

At the back is the main shell; all in one piece. The eight parts in front and to the left are the sand boxes, which fix onto the sides. Each sand box has a locating peg which fixes into a hole on the side of the shell. Next to the sand boxes are the crew and control consoles for the cab interior. Below the two crew is a square plug which acts as a screw mount for holding the fuel tank on. Next to the crew are the horns, these again have a simple peg which fixes into a hole in the shell. The fuel tank is next to the horns and the two round parts are the drive shaft extenders. The final two parts at the bottom are the 3D printed stainless steel chassis extenders. The plastic parts have been printed in Shapeways’ Frosted Ultra Detail. Although the Frosted Extreme Detail has a smaller layer thickness than FUD giving an even better finish, this was a test print and I wanted to see how it would come out before going to the best quality. But even in FUD the details are clear and smooth and I will be very happy with this as an actual model. Here are some close-ups of some of the detail

As normal with parts printed in FUD or FXD they need to be cleaned to remove the waxy residue, so after a rinse of in warm soapy water they spent 24 hours submerged in Goo Gone.

While the parts where getting cleaned I prepared another chassis. I already had one extended chassis but as I have made some improvements to the chassis extenders I wanted to make up another. As I have already covered this procedure in a previous post, which can be found here, I will only show the differences today. I will be making a downloadable PDF available with full instructions soon.

As before I started with a standard Con-Cor U50/Turbine chassis.

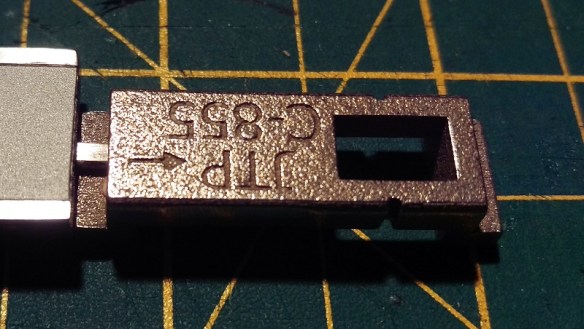

The new chassis extenders have been tweaked in several places but the most obvious is the introduction of a forward arrow on both parts, this should help with orientation in the chassis.

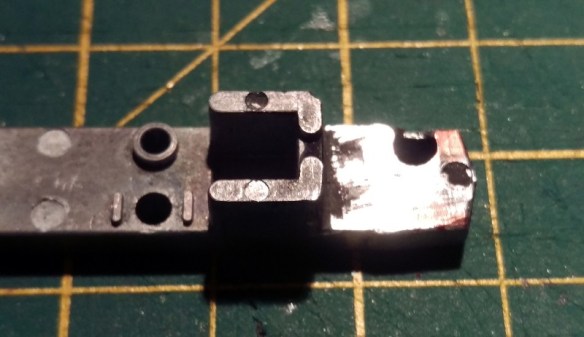

The top section should be done first. And this simply means removed the section highlighted below. I used a cutting disc in a Dremel type tool.

The three parts where then glued together. The key is to make sure the dog leg part of the chassis extender is flush with the underside of the remaining parts. There should be a small gap at the location where you made the cut. That way the chassis will be the correct length and it will be easer to keep it square.

The three parts where then glued together. The key is to make sure the dog leg part of the chassis extender is flush with the underside of the remaining parts. There should be a small gap at the location where you made the cut. That way the chassis will be the correct length and it will be easer to keep it square.

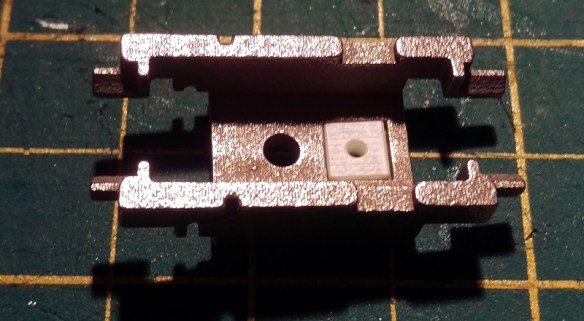

Unlike last time, I also need to make some cuts at the front because the body of the locomotive is narrow below of the cab. The two wings need to be cut off as shown below.

Also two notches need to be made. I will give the sizes of these in the downloadable PDF. The top notch ended up a bit larger than I had hoped because of the screw hole. You could simply cut it all off but I want to keep as much weight as possible.

As I pointed out earlier there is a plastic square plug used to screw in the fuel tank.

This simply fits into the square hole in the bottom chassis extender.

It will be held in by the motor and when you screw on the fuel tank, using the same screw from the U50/Turbine fuel tank, it will pull tight.

With the bottom chassis section it is important to cut it as close to the parts that hang down as possible. Other wise you may end up with a gap in the chassis frame. Indicated below is the section to be removed.

Once fully assembled it should look like this.

My C-855s will be DCC so I have installed a decoder in the space at the rear of the locomotive.

The next step was to test fit the shell. In the photo above you can see a square hole at the front of the fuel tank. Inside the shell is a tapered peg so as the shell slides onto the chassis the shell will spread untill the peg pops into the hole holding it tight.

The shell is nice fit and once the pegs locate into the fuel tank you can comfortably pick it up by the shell and it wont fall apart.

One of the identifying details on the C-855 is the large sand boxes on the side and because of the locating pegs these can easily be clipped into place. I have made them a separate part to make it easer to paint the model. In the photo below they are not glued in place but simple press fitted.

But as great as the loco now looks there are still lots of parts missing. And today I took delivery of the first batch of etched brass Additions for this loco.

As I am going to paint the loco a lot of the parts are not ready to go on yet, plus I only got them today, but to give you and idea of what the finished loco will look like here are some picture with some of the brass Additions loosely fitted.

Because just about all the brass Additions have mounting holes or slots they should be very easy to install. The handrails drop into the top of the sand boxes which makes them easy to align. There are a lot more parts to be added and some, like the ladders, can’t be shown yet as the handrails need to be fixed properly first but as you can see from the image below even the windscreen wipers have mounting holes. It has swung to its natural hanging position but once glued in, it will line up with the left of the window frame.

I want to do a few checks to make sure everything is where it should be for all the brass Additions and then the shell will be made available on Shapeways. I think that will happen in the next few days. The chassis extenders are available now and can be ordered in sets of one, two or three by clicking on the links below.

Set of one C-855 chassis extenders.

Set of two C-855 chassis extenders.

Set of three C-855 chassis extenders.

There is an option to print the chassis extenders in WS&F and FUD which are both cheaper than the stainless steel but you will lose a lot of weight and please note: I have not tested them in these materials.

Although I normally post on a Monday I will do an extra post this week to let you know when the C-855 body and parts are ready as I know several of you are keen to get them. If you order the chassis extenders now you can add the shell to your order at Shapeways without paying for shipping twice, as long as you do it in good time. I also have brass Additions in stock, these are £6 GBP each. Please contact me though contact page or email me if you would like to order some.

The next step, apart from painting and finishing the C-855, is to finish drawing the C-855B. The chassis will be exactly the same so the extenders will be need for that too. I will also be drawing a dummy chassis for both locos and will be sharing that with you soon.

Before I even think about ballasting track I always do lots of running on the layout to make sure everything works okay. The track is glued down onto a cork road bed which in turn is glued to the module top. The cork is important for a few reasons which I will cover in a bit. In the picture above you may have noticed that the track has been weathered. This is not a necessity but it adds the realism I like to see; railroads are not a clean place.

Before I even think about ballasting track I always do lots of running on the layout to make sure everything works okay. The track is glued down onto a cork road bed which in turn is glued to the module top. The cork is important for a few reasons which I will cover in a bit. In the picture above you may have noticed that the track has been weathered. This is not a necessity but it adds the realism I like to see; railroads are not a clean place.

You must be logged in to post a comment.