The Con-Cor Turbine and U50 chassis has been around for many years and has always been a solid runner. However, by modern standards, the motor in the chassis is rather noisy and draws a lot of current. In this post I’ll share with you how myself and Bob Norris replaced the motor to improve these issues.

The chassis, as pictured below, has a central motor powering two drive shafts which in turn power the two outer trucks. The inner pair is unpowered. The design has been used for the GE U50 model since 1973, which interestingly was first made for Con-Cor by Kato. This chassis was also used for the GE 4500 Gas Turbine model which was released in 1975.

And more recently it’s been used by me for the Alco C-855 as shown below, stretched and fitted with a DCC decoder. You can read more about the stretching of the chassis here or by searching this site for C-855.

The first three C-855s I made went to Bob Norris and the chassis have been running well but recently we have added sound decoders to them and this started giving us a few problems. Firstly the motors are fairly noisy and secondly they draw lots of current. When pulling a heavy train with the sound at full volume the sound decoders have been known to shut off and then start behaving erratically. Now I know the original three ordered by Union Pacific didn’t last long as they were prone to failure but that wasn’t the aim here!

So after doing some investigating we did a stall test on one of the motors and we discovered that the peak amperage can sometimes go over the maximum for the decoder by a fair amount. To find out what a stall test is and how to do it please see this post.

Below is a short video of a C-855, running light engine with the sound off so you can hear the motor whining. The clicking is the Digitrax DCC controller notching up and down.

To solve the issues a new motor was found for the chassis. Coincidently it is also made by Kato, although a much newer design. The Kato motor 420000 is advertised as a replacement motor for Atlas N Scale. We found them on eBay though the seller Soo-Much-Stuff.

The motor comes with no gears on the drive shafts which is ideal. Below you can see the new motor on the right and the old on the left.

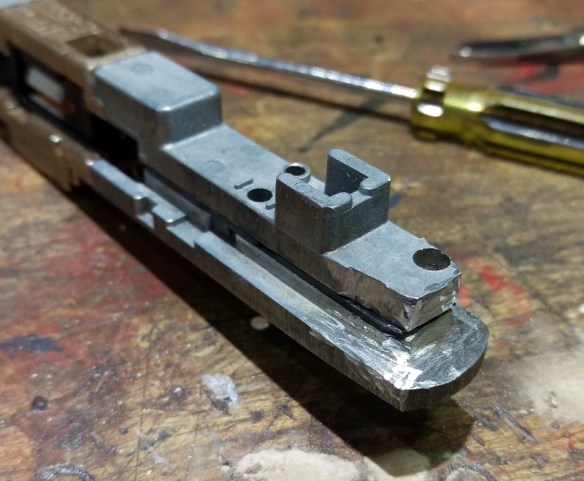

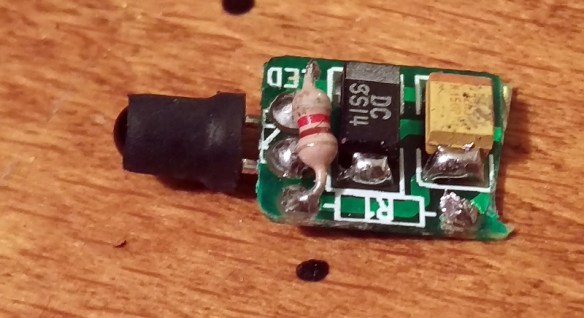

The old motor, as shown below, sat in the middle of the raised area of the chassis and the gears ran inside larger diameter cup gears.

The chassis un-screws and separates easily allowing the motor, drive shaft and motor cradle to be removed.

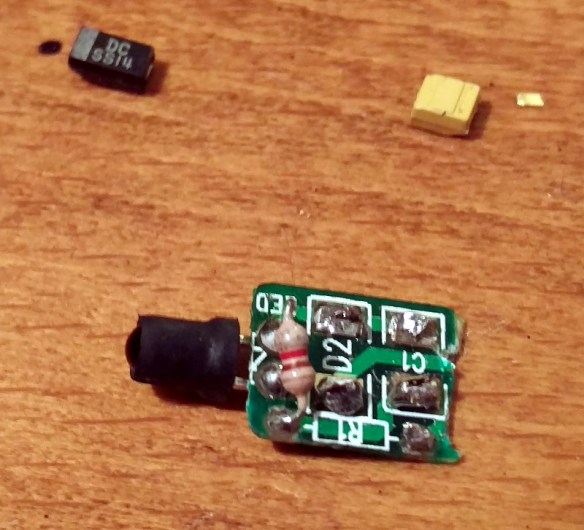

The gears on the old motor (top in the photo below) need to be removed and fitted to the new motor. They are simply press fitted and can be removed by applying pressure behind the gear. Not too much pressure or you will spend ages looking for the gear on the other side of the layout, don’t ask me how I know this!

To fit them to the new motor the process is the same, just the other way around.

The gear needs to slide on far enough so the drive shaft is almost at the other side. Note, this was done for the C-855 extended chassis, the U50 and turbine chassis should be the same but it’s a good idea to check as you go. If the gear slides on too far it may not make good contact with the cup gear.

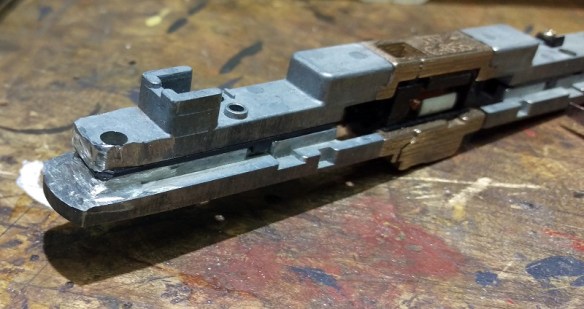

With the gears fitted the tabs can be bent up ready for soldering wires to. If you are doing this for a DC locomotive the tabs will need to be in the same positions as the motor you have just taken out.

The bottom tab pokes through the motor cradle.

Upon test fitting we discovered the motor was sightly smaller than the original which caused it to sit a bit low. To solve this a plastic shim was made to fit in the bottom of the cradle.

The cradle was then fitted back into the chassis ready for the motor.

As you can see below the gears now fit nicely into the cup gears. If the shim was too thick the cup gears would be lifting and this would cause noise and strain the motor.

The wires can now be added to the motor. There is a channel formed in the C-855 chassis extender on either side so you have a choice on where to run your wire.

The chassis is now fully reassembled and ready for testing.

Below is another short video showing how quietly the new motor runs.

With all three units converted to new motors the performance should be greatly improved and hopefully I will get some video of them running soon to share with you.

Thanks go to Bob for the photos and videos of the motor swap.

The new Shapeways order has now been shipped so next week I will start showing you some of the products I’ve been sharing over the last few weeks.

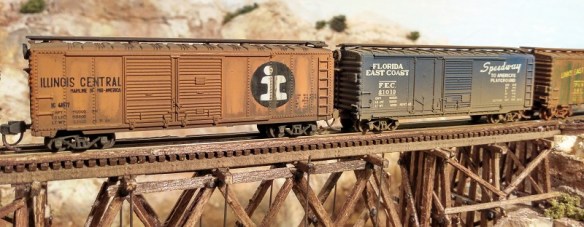

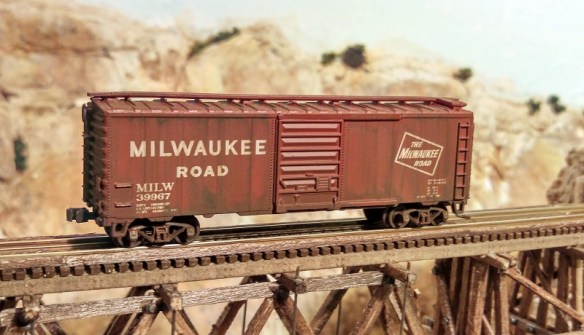

As a comparison; below is a factory weathered freight car, on the left, alongside my weathered freight cars.

As a comparison; below is a factory weathered freight car, on the left, alongside my weathered freight cars.

And don’t forget the windows in the doors, that piece needs to be 5mm by 3mm.

And don’t forget the windows in the doors, that piece needs to be 5mm by 3mm.

Later that evening C-855 no 60 received its handrails and ladders which made a dramatic change to the appearance of the loco. All that’s left now is to finish painting the trucks and pilots and weather her up.

Later that evening C-855 no 60 received its handrails and ladders which made a dramatic change to the appearance of the loco. All that’s left now is to finish painting the trucks and pilots and weather her up.

You must be logged in to post a comment.