If you have been following my blog for a while you will know that I have been working on an N Scale Alco C-855. You can read the first part here. In this week”s post I will share with you what I have done to finish the A unit and get it ready to order a test print.

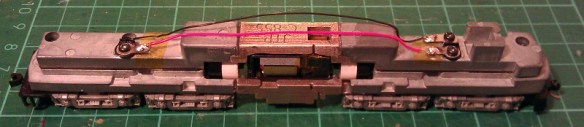

In my last post about the C-855 I showed you the first print of the metal chassis extenders and how I fitted them into the Con-Cor Turbine/U50 chassis.

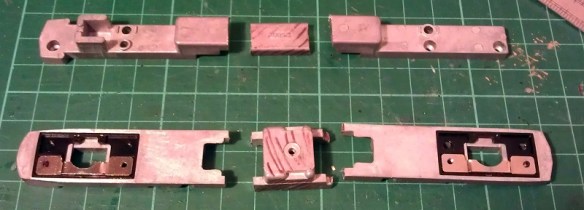

This chassis runs well, and pulls even more than in its original counterpart; probably due to the increased weight. However there were a few issues with the print so I have improved the 3D model to rectify them. In the image below you can see both parts from the top and bottom.

The space for the motor has been widened by a fraction as the motor was a tight fit in the first print. The wire channel has also been increased in size so the motor wire is a better fit. I have also made some changes to the bottom of the lower section. The arrows point forward on both parts to help with orientation when assembling the chassis. There is now a rectangular nub that sticks out to locate the fuel tank on the bottom of the locomotive. Also a square hole has been added which has been designed to take a 3D printed screw fixing which is used to hold on the fuel tank. The exploded view below shows how these fit together.

I have designed this assembly so the original Con-Cor turbine/U50 screw can be used athough any similar size screw will work.

This section of the fuel tank is only the bottom as the sides are part of the main body. Looking at the image above you can see a square hole in the side of the fuel tank, this is designed to receive a nub sticking out from the shell. You can see the nub in the image below which shows half of the shell. As the bottom of the fuel tank is fixed with the screw it becomes a solid fixing for the shell.

As with a lot of ready-to-run locomotives, to remove the shell it can simply be spread in the middle and lifted off.

To make painting and adding decals to this model easier the four large sand boxes on the sides have been made as separate parts. The rear six are the same but the front pair are longer as they have to step over parts of the chassis. The shell has slotted fixings in the side of the running board to receive the sand boxes so they can be securely fitted. The holes on the tops are handrail fixings.

As with my DT6-6-2000 and RT-624 locomotives my C-855 will come with crew for the cab, Bert and Ernie. The controls on the console are very basic but this is N scale so once they are inside the cab it will be hard to see anyway.

Because of the shape of the chassis, there is a large chunk of metal sticking up into the cab, the crew had to be pushed to the sides. There are locator pockets in the shell walls to receive the crew once they have been painted. As the C-855s ran in an A-B-A configuration you may not want crew in the rear A unit so they can simply be left out.

Below you can see the crew in their place with half the shell removed.

This view also shows you the headlight fitting in the roof of the cab. The shell has been shaped to receive a standard 3v 2mm LED. A nice warm white LED can be fitted directly into the roof of the cab and a pair of headlights will shine from the front. This area will need to be painted black on the inside to prevent the light from shining through the shell.

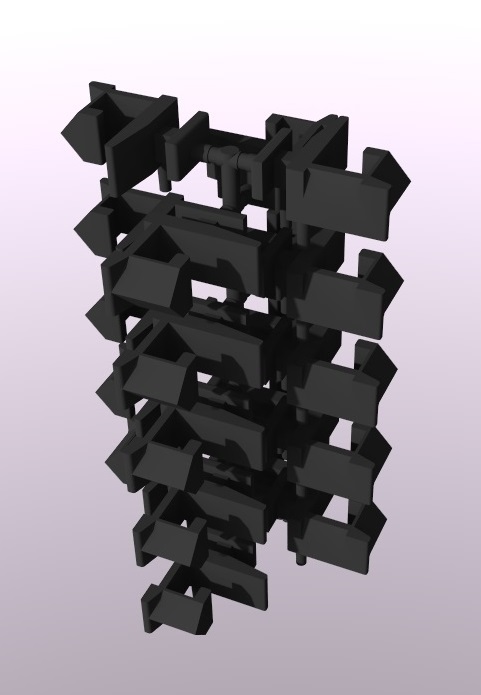

Even the horn is a separate 3D printed part; this is both to make it easer to paint and to protect it from being knocked off in shipping. Below you can see all the 3D printed plastic parts for one C-855. The large gears are the drive shaft extenders which are needed when the chassis is extended.

In the cab you can see lots of holes; this is because all the grab irons and handrails plus many other details are brass parts that will be supplied in a brass Additions set. The set will also include some of the metal walkways, windscreen wipers, side ladders, MU hoses and sun visors for the cab.

So putting this all together, this is how the N Scale C-855 will look. Please note the trucks under the 3D model are not yet correct.

The end will have brass grab irons up the center and walkways over the air intakes.

The cab with all of its brass parts will be well detailed

Overall this monster of a locomotive has an imposing presence.

The next step is to finish the drawings for the B unit and design a dummy chassis so an A-B-A set can be made without powering all the units, if required.

The new 3D printed metal parts as well as the 3D printed plastic parts for the C-855 have new been sent for test printing so I should have the first N Scale C-855 within the next few weeks. Once it arrives and I have cleaned up all the parts I will share some images with you.

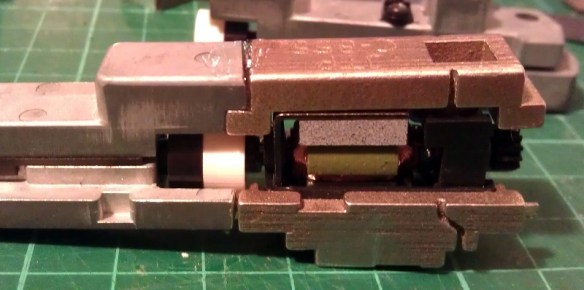

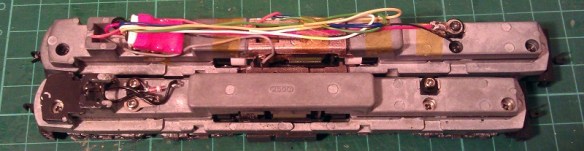

Now the top section was complete I could position and glue in the motor section. You may have noticed I left the top and bottom sections of the chassis bolted together throughout most of this. I did this to help ensure everything was in the correct place, particularly when it came to fitting the motor section. As it happened I did cut the lower front chassis section a bit short and if I had glued the whole bottom section together tightly it would have been too short. However as the chassis parts were bolted it all worked out well and below is the chassis glued together.

Now the top section was complete I could position and glue in the motor section. You may have noticed I left the top and bottom sections of the chassis bolted together throughout most of this. I did this to help ensure everything was in the correct place, particularly when it came to fitting the motor section. As it happened I did cut the lower front chassis section a bit short and if I had glued the whole bottom section together tightly it would have been too short. However as the chassis parts were bolted it all worked out well and below is the chassis glued together.

The detail on the tool boxes came out very well in the WS&F, it had the level of detail necessary for this part.

The detail on the tool boxes came out very well in the WS&F, it had the level of detail necessary for this part.

Each end of the shell has two pegs to mount a Kadee coupler; I have used No.5 couplers.

Each end of the shell has two pegs to mount a Kadee coupler; I have used No.5 couplers.

You must be logged in to post a comment.